UNIQUE PROGRAMMING TOOL

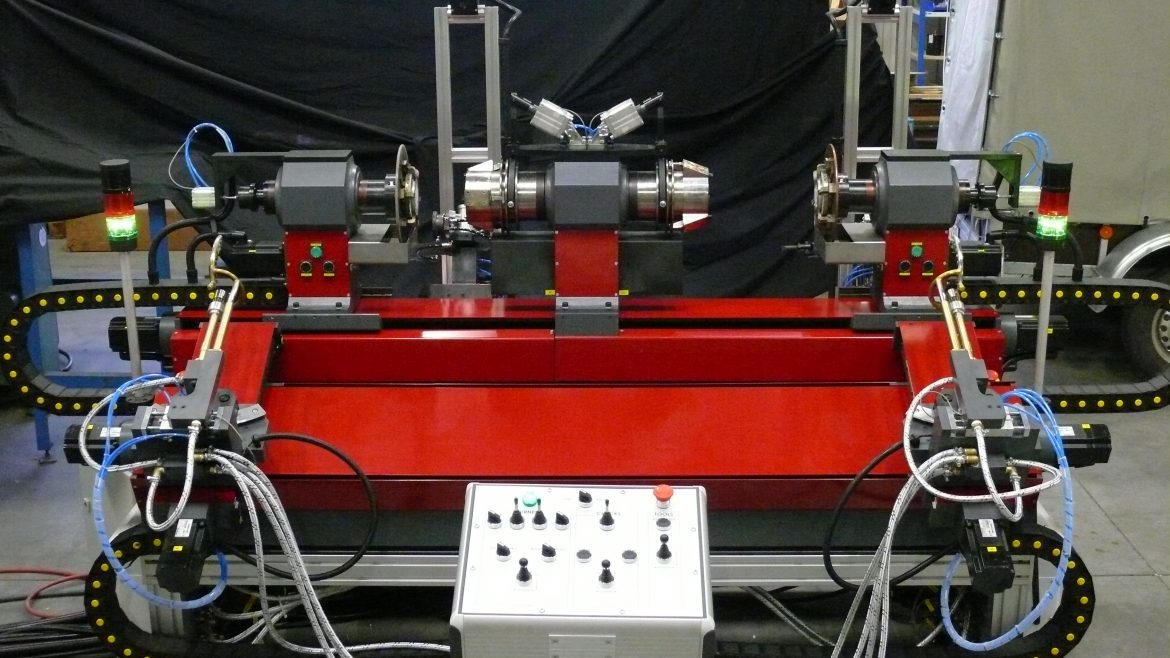

Remote control. Using joysticks, potentiometers and other controls, a glassblower can produce a reference piece on an automatic machine. During this operation, called acquisition, the machine records all actions made by the glassblower, as well as thermographic and dimensional maps.

The software analyses all the information recorded during the acquisition, finds correlations between the actions made by the glassblower and the thermographic and dimensional information then automatically generates a production programme. Corrections can be made directly in the program to improve the quality or the production specials.

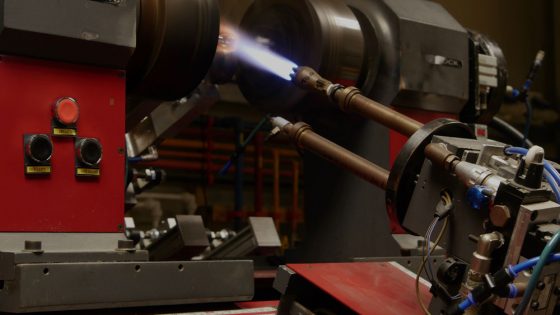

As a glassblower works on a manual lathe, he is working in closed loop. He carries out an operation, looks at the effect of this operation on the glass and consequently decides about his next action.

The effect analyzed can be linked to the viscosity of the glass or its shape. This method allows the glassblower to adapt to variations in his working environment (dimensions of tubing, flame power) to produce the same final result from various working conditions.

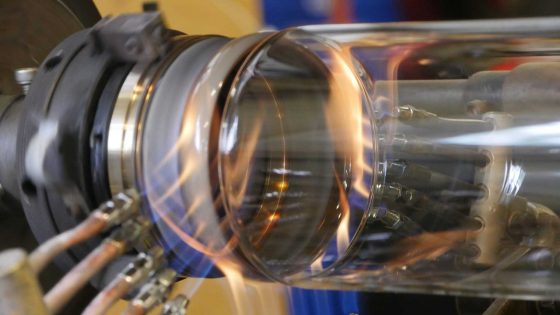

These thermographically controlled lathes are roughly working on the same principle. The embedded thermographic camera continuously measures the temperature profile and the dimensions of the working glass at locations defined by the program and adapt the programmed actions according to the result of these measurements.

Taking into account the machine is able to perform these measurements with a far greater accuracy than a glass blower, the final result is also more accurate and repetitive, with tolerances up to ±0.05 millimeter.